Description

Material: Blades designed for metal sandwich panels are often made from Bi-Metal, which combines High-Speed Steel (HSS) and High Carbon Steel (HCS). This combination provides the blade with both flexibility and durability, necessary for cutting through the metal layers and the core material.

Tooth Design: These blades often have a moderate Teeth Per Inch (TPI) count, typically around 10-14 TPI. This tooth design strikes a balance between efficient cutting through metal and reducing wear when cutting through the core material.

Blade Length: The blade lengths for cutting metal sandwich panels can vary, but common lengths range from about 100mm (around 4 inches) to 150mm (around 6 inches).

Blade Type: Jigsaw blades come in two main types, T-shank and U-shank. The type you need depends on your jigsaw’s compatibility. Most modern jigsaws use T-shank blades.

Cutting Style: These blades are specifically designed for straight cuts in metal sandwich panels, ensuring precise and clean cuts through both the metal layers and the core.

Working Material: As the name suggests, these blades are specifically designed for cutting through metal sandwich panels, which consist of metal layers and an insulating core.

Ground and Set Teeth: The teeth on these blades are often ground and set, providing an aggressive cutting action suitable for metal and maintaining flexibility for the sandwich panel’s core material.

Additional information

| Weight | 20 kg |

|---|---|

| Dimensions | 20 × 20 × 20 cm |

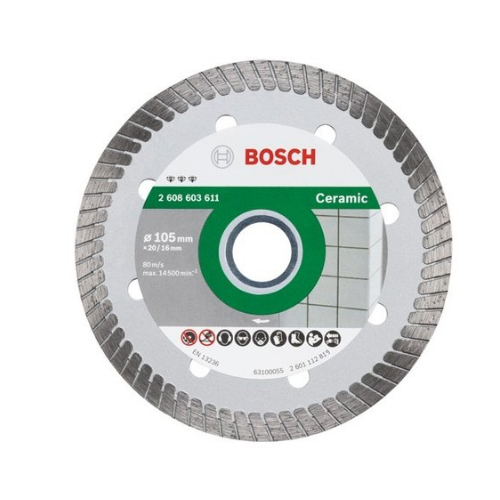

| brand | Bosch |

| condition | New |

| warranty | 2 Years |

| power-source | Cordless |